c.suite

General characteristics

c.suite is the development suite for the c.pCO family controllers, completely upgraded compared to the previous 1tool environment.

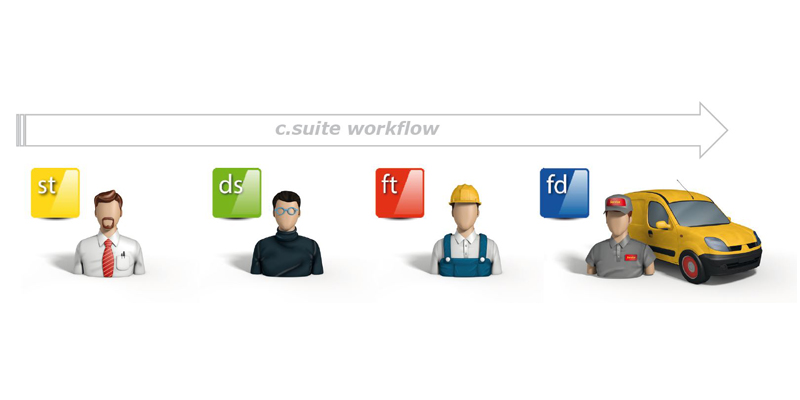

c.suite is in fact designed as a set of interdependent modules, each dedicated to a specific area of the development of a control system for an HVAC/R unit or system.

c.suite allows a team with different skills and specialisations to work together on the same project, increasing the efficiency of each individual team member. The application software is developed in logically independent parts by different developers, each of whom can use the most suitable tool for the specific area (temperature control, interface, connectivity, etc.).

Development environment:- c.strategy: environment where expert algorithm programmers prepare the heart of the application program. The features of this programming environment are:

- - total independence of the programming logic from the hardware and devices connected to the network;

- - availability of languages compliant with IEC 61131: ST (structured text), FBD (function block diagram), SFC (sequential function chart), LD (ladder diagram), also used simultaneously;

- - management of 32-bit data types, floating point, arrays and native structures;

- - on-target debugging via USB or Ethernet port.

For the development of interfaces and definition of configurations, the following modules are available:

- c.mask: the developer of the user interface works in a dedicated environment. c.mask can be connected to the logic developed in c.strategy, so that any changes made by the temperature control developers are available in real-time to the interface designer.

- c.design: definition of configurations, such as controller type and size, inputs/outputs, client/server protocols, default parameter values, data logger, network address and user management, connection to tERA cloud services.

Command line tools:

- c.factory: used to program the controller in the production flow by loading the application program and the desired unit configuration during assembly. It is designed to allow integration with the most-commonly used process software on production lines, and can be integrated with a barcode reader.