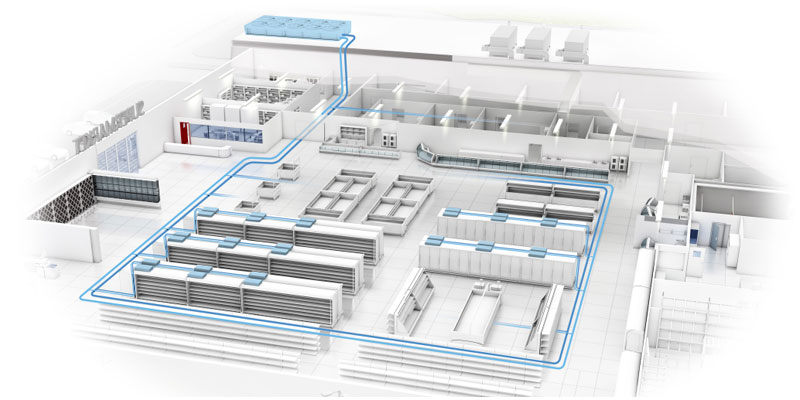

The most common systems used for temperature and humidity control in datacenters are CRAC units (Computer Room Air Conditioners), traditionally also known as CCU (Close Control Units). CRAC units are normally installed around the perimeter of the server room, or adjacent to it, and use the raised flooring to introduce cooled air via a refrigerant circuit or water-source heat exchangers supplied by a chiller, so as to absorb the heat loads generated by the electronic equipment; often these are in fact called "perimeter" units. In modern datacenters, the layout of servers into "hot aisles and cold aisles" has led to the development of "in row" units, installed directly between the servers for more localised cooling, ideal for high density heat loads. The high cooling capacities required, even up to 20 times higher than in comfort applications, mean energy saving technology is the preferred choice.

Cooling can also dehumidify the air, and therefore very often CRAC units are fitted with humidifiers so as to bring the humidity level back within an acceptable range and reduce the risk of electrostatic discharges. Generally, these units work in unsupervised places, and with limited intake of fresh outside air, therefore dehumidifying means unnecessary energy consumption for the overall sensible cooling needed, and requires further humidifier operation: dehumidification is at times used in systems located in places with high humidity.

Continuous innovations in this field require the development of new units and sophisticated functions; most CRAC units are also able to communicate with one another to ensure synergic operation and redundancy, and often share data (alarms, states, probe readings...) .