humiSteam Basic

General characteristics

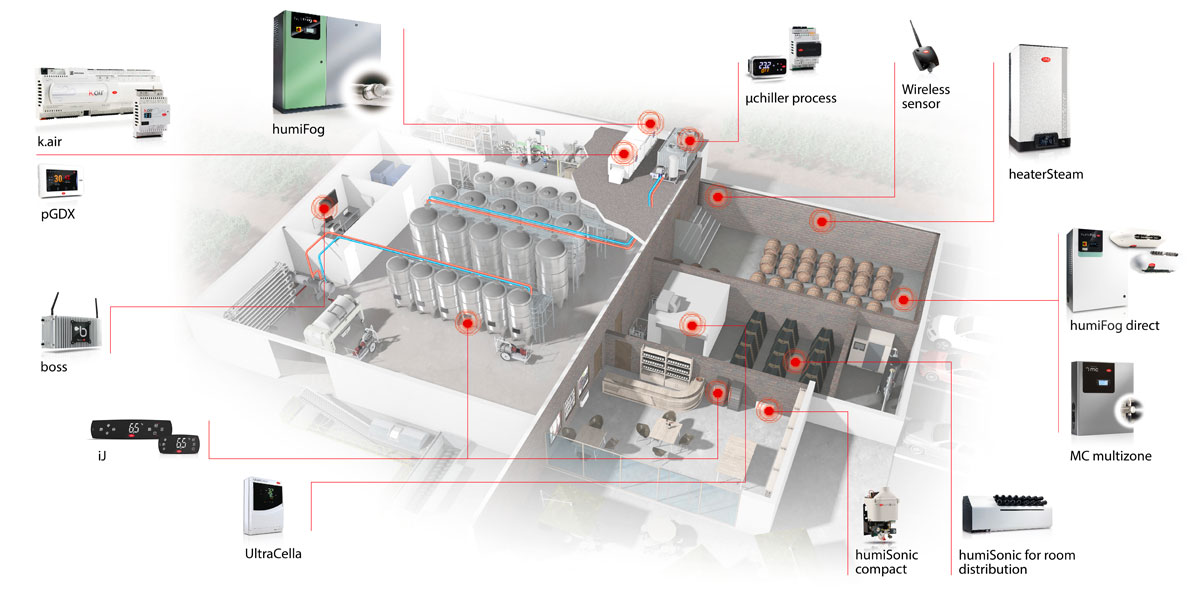

humiSteam basic (Y) is suitable for installation in civil environments, offices, hospitals and industrial facilities, and is designed for installation both in rooms, using the steam blower, and air ducts, using the linear steam distributors.

humiSteam basic is ideal for applications where steam production is controlled by an external signal, i.e. BMS or humidistat, and comes in a range from 1.5 to 65 kg/h.Steam production is controlled in the following modes:

- ON/OFF mode: a simple contact (for example, a humidistat) starts/stops steam production;

- proportional mode: the humidifier produces a quantity of steam that is directly proportional to the signal (0-10 V, 2-10 V, 0-20 mA, 4-20 mA) generated by the external controller, always between 20% and 100% of maximum capacity;

- proportional mode: based on the set point and a humidity probe reading.

Type "Y" humidifiers have a display with numbers and icons that shows the operating conditions and any diagnostic information extremely clearly and intuitively.

In addition, they come with RS485 interface with Modbus protocol for remote configuration and control via BMS.-

Plus

• AFS system (Anti Foaming System): detects foam to prevent droplets of water being carried by the steam;

• cylinders with galvanised electrodes and anti-scale filter at bottom, openable cylinders also available;

• steam production with continuous modulation from 20% to maximum rating ;

• built-in conductivity sensor and control software to optimise energy efficiency and maintenance costs, with constant performance throughout cylinder life.

• automatic water drain after 3 days of inactivity Video